Small-Scale Manufacturing Term Finder

Find Your Manufacturing Term

Enter your annual production volume and workforce size to determine which small-scale manufacturing category best describes your business.

When people talk about Small-scale manufacturing production carried out in limited volumes, often within a local or regional setting, using modest equipment and a small workforce, they’re usually referring to a range of activities that sit between home‑based craft work and full‑blown factory output. In plain English, it’s the sweet spot where a business can churn out dozens to a few thousand units a year without the massive overhead of a big plant. This article unpacks the exact name for that niche, explores the related jargon, and shows how it fits into today’s industrial landscape.

Key terms - what people actually call it

Over the years the concept has been labeled in a few different ways. The most common labels are:

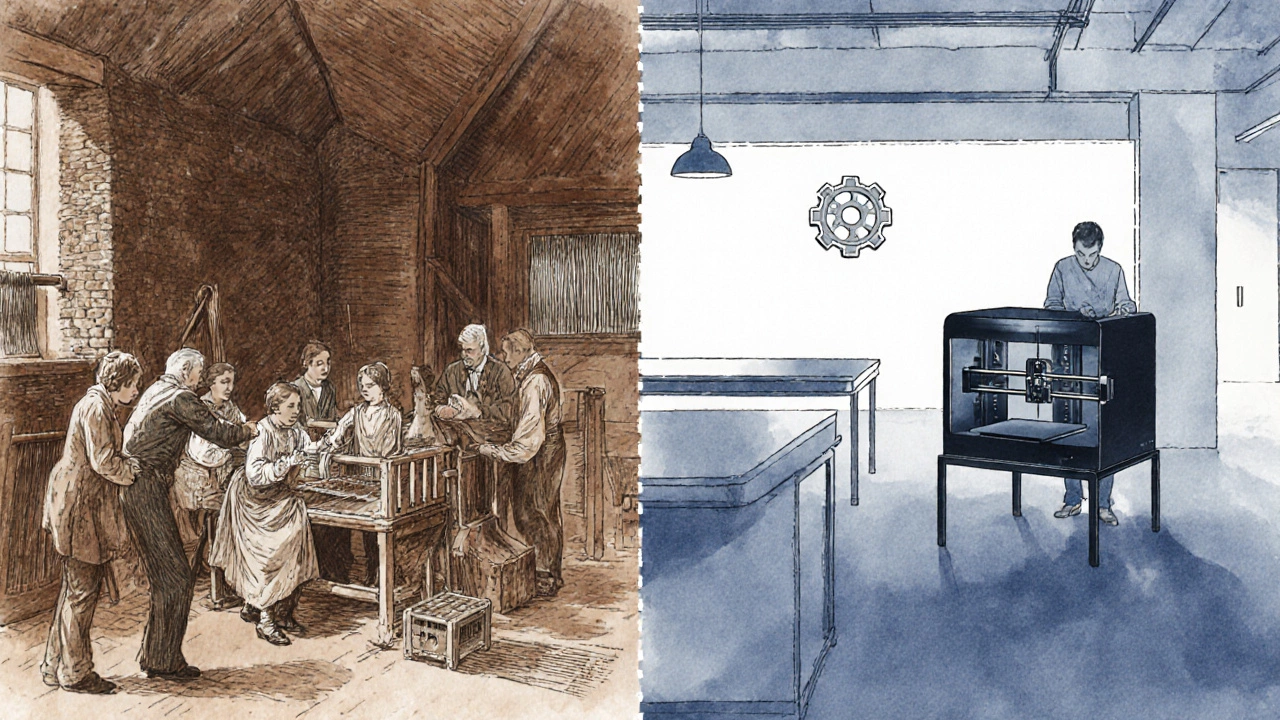

- Cottage industry traditional, often family‑run production that takes place in a home or small workshop

- Micro‑manufacturing high‑tech, low‑volume production using advanced tools like 3‑D printing

- Artisan production hand‑crafted goods where skill and design outweigh sheer output

- Light manufacturing processes that involve minimal material handling, low energy use and small batch sizes

- Job shop a flexible workshop that produces custom parts in short runs

All of these fall under the umbrella of small scale manufacturing, but each highlights a slightly different angle - be it tradition, technology, or flexibility.

Historical backdrop

The roots of small‑scale manufacturing go back to the domestic workshops of the Industrial Revolution. In Britain, the “put‑out system” shipped raw material to weavers’ homes, letting them finish textiles in small batches. By the late 19th century, the term “cottage industry” became common, especially in the Midlands and Yorkshire, where families produced metal tools, pottery, and textiles from their backyards.

Post‑World War II, as mass production took hold, many of these workshops shrank or vanished. Yet the 1990s saw a revival thanks to the rise of niche markets, DIY culture, and later, digital fabrication tools. Today, a Birmingham designer can 3‑D print bespoke bike frames in a loft while a Nottingham food maker produces artisanal cheese for local supermarkets - both clearly operating in the small‑scale realm.

How it differs from mass and bespoke manufacturing

Understanding the distinctions helps you pick the right label for your venture:

- Volume: Mass production pushes tens of thousands to millions of units per year. Small‑scale stays under a few thousand, often under 5,000.

- Capital intensity: Large factories demand huge upfront investment in machinery and facilities. Small‑scale setups can start with a single CNC router or even a workbench.

- Customization: While mass production emphasizes uniformity, small‑scale manufacturing can accommodate frequent design tweaks without costly retooling.

- Supply chain: Big firms rely on global logistics; small operators often source locally, reducing lead times and carbon footprints.

Because of these traits, the industry often intersects with Lean manufacturing a philosophy that eliminates waste and focuses on value‑added steps, even if the scale is modest.

Typical sectors that thrive on small‑scale production

Some industries naturally lend themselves to limited‑run manufacturing:

- Food & beverage: Craft breweries, specialty chocolate makers, and small‑batch spice blends.

- Textiles & fashion: Bespoke tailoring, hand‑dyed fabrics, and limited‑edition streetwear.

- Electronics: Custom PC cases, boutique audio equipment, and prototype consumer gadgets.

- Mechanical components: CNC‑machined brackets, 3‑D printed prosthetic parts, and low‑volume aerospace components.

- Furniture & décor: Hand‑crafted wooden tables, reclaimed‑material lighting, and small‑batch ceramics.

Each of these benefits from the ability to test designs quickly, respond to niche demand, and maintain a strong brand story that resonates with consumers seeking authenticity.

Benefits and challenges

Benefits

- Speed to market: Short lead times and quick iteration cycles.

- Lower overhead: Minimal facility costs, often run from home or shared workshops.

- Brand differentiation: Storytelling around craft, locality, and sustainability.

- Flexibility: Easy to pivot product lines based on market feedback.

Challenges

- Scaling limits: Moving from 500 to 5,000 units can require new equipment.

- Regulatory compliance: Small producers still must meet safety, environmental, and labeling laws.

- Access to finance: Banks often view low‑volume businesses as higher risk.

- Talent retention: Skilled artisans may be scarce or command premium wages.

Government support and policy landscape (UK focus)

The UK government recognises the role of small‑scale manufacturers in preserving skills and boosting regional economies. Key programmes include:

- Manufacturing Innovation Centre (MIC) grants: Funding up to £250,000 for equipment upgrades.

- Skills Bootcamps: Free training for CNC machining, digital design, and additive manufacturing.

- Made Smarter Regional Hubs: Co‑working spaces that provide access to shared tools and mentorship.

- Export Support: The Department for International Trade offers market‑entry advice for boutique manufacturers eyeing EU and US markets.

These schemes aim to reduce the capital gap, upskill the workforce, and help small producers reach broader audiences.

Comparison of common terminology

| Term | Typical Output Range (units/yr) | Workforce Size | Key Industries |

|---|---|---|---|

| Cottage industry | 10‑500 | 1‑10 | Textiles, handicrafts, food |

| Micro‑manufacturing | 100‑2,000 | 5‑30 | Medical devices, aerospace parts |

| Artisan production | 50‑1,000 | 2‑15 | Furniture, jewellery, specialty foods |

| Light manufacturing | 500‑5,000 | 10‑50 | Electronics, plastics, metal stamping |

| Job shop | 200‑3,000 | 5‑25 | Custom tooling, prototype components |

Quick checklist for launching a small‑scale manufacturing venture

- Define your niche: What problem does your product solve and who values craft?

- Choose the right term: Use "cottage industry" for heritage‑focused brands, "micro‑manufacturing" if high‑tech equipment is central.

- Validate demand: Run a small pre‑order campaign or attend local maker fairs.

- Secure equipment: Consider shared workshops (e.g., Made Smarter hubs) to keep capital low.

- Map regulatory requirements: Check UKCA marking, food safety standards, or CE marking as needed.

- Plan the supply chain: Source materials locally to reinforce the "Made in Britain" story.

- Apply for grants: MIC, Innovate UK, or regional skill bootcamps can offset costs.

- Set up production SOPs: Even small runs benefit from documented processes to ensure consistency.

Frequently Asked Questions

Is a cottage industry the same as small‑scale manufacturing?

They overlap, but a cottage industry specifically refers to home‑based, often family‑run production rooted in tradition. Small‑scale manufacturing is a broader umbrella that includes modern workshops, micro‑factories, and even light‑robotic lines.

What annual output qualifies as "small scale" in the UK?

While there’s no hard legal definition, most analysts set the ceiling at roughly 5,000 units per year. Anything above that typically moves into the "light manufacturing" category.

Can I claim government grants if my business is a home‑based workshop?

Yes. Grants such as the Manufacturing Innovation Centre funding focus on the equipment and capability upgrades, not the location. You’ll need a clear business plan and evidence of market potential.

How does micro‑manufacturing differ from 3‑D printing hobbyists?

Micro‑manufacturing uses additive or subtractive processes at a production‑grade level - think industrial‑grade printers, calibrated for repeatability and compliance. Hobbyists often work with desktop printers that lack the tolerance or certification needed for commercial sales.

Is there a UK certification required for small‑scale food producers?

Food businesses must register with your local authority and comply with the Food Hygiene Regulations. If you plan to sell nationally, you may also need a HACCP plan and, for certain products, a specific food safety scheme like Red Tractor.

Whether you label your operation a cottage industry, a micro‑manufacturing lab, or simply a small‑scale manufacturing startup, the core idea stays the same: produce high‑quality, limited‑run goods that resonate with niche markets while keeping overhead lean. Armed with the right terminology, the right support schemes, and a clear go‑to‑market plan, you can turn a modest workshop into a thriving business that adds value to the local economy and keeps the spirit of British manufacturing alive.