Profit Margin Calculator for Small-Scale Manufacturing

Calculate Your Manufacturing Profitability

Determine potential profits for your small-scale manufacturing business based on production costs and selling price. Use these estimates to plan your startup or evaluate new product lines.

When people think of manufacturing, they picture huge factories with robots and assembly lines. But some of the biggest profits today come from small-scale operations - often run by just a few people in a garage, warehouse, or rented unit. The question isn’t just what manufacturing makes the most money, but which types can turn $50,000 in startup costs into $500,000+ in annual net profit without needing a corporate budget.

High-Margin Manufacturing That Doesn’t Need a Factory

You don’t need to build cars or microchips to make serious money. Some of the most profitable small-scale manufacturing businesses have low overhead, high demand, and repeat customers. The real winners? Products that solve a specific problem, have little competition, and can be sold directly to consumers or niche B2B buyers.

Take specialty food processing. A small batch of artisanal hot sauce made in a home kitchen can cost under $1.50 to produce and sell for $12 a bottle. Sell 3,000 bottles a year? That’s $36,000 in revenue with $28,000+ profit after ingredients, labels, and shipping. Companies like Frank’s RedHot started as a small family operation in Louisiana before becoming a national brand. Today, hundreds of small makers do the same thing - just on a local or regional scale.

Pharmaceutical Manufacturing: The Hidden Goldmine

Don’t let the word "pharmaceutical" scare you off. You’re not making pills in a FDA-certified plant. You’re making topical creams, salves, and ointments for skin conditions, muscle pain, or natural remedies. These products are regulated as cosmetics or dietary supplements, not drugs - which means you can make them legally in a clean room without a $2 million facility.

A small manufacturer in Ohio makes a CBD-infused muscle rub using just five ingredients. Each 4-ounce jar costs $2.80 to make. They sell it for $45. They produce 1,200 jars a month. That’s $54,000 in monthly revenue. After taxes, labor, and shipping, their net profit is around $38,000 a month. That’s over $450,000 a year from a 300-square-foot workspace.

Why does this work? People pay premiums for natural, effective, locally made products. And they’ll subscribe. One maker I spoke with has 800 recurring customers who buy every 45 days. That’s predictable cash flow - the holy grail for small manufacturers.

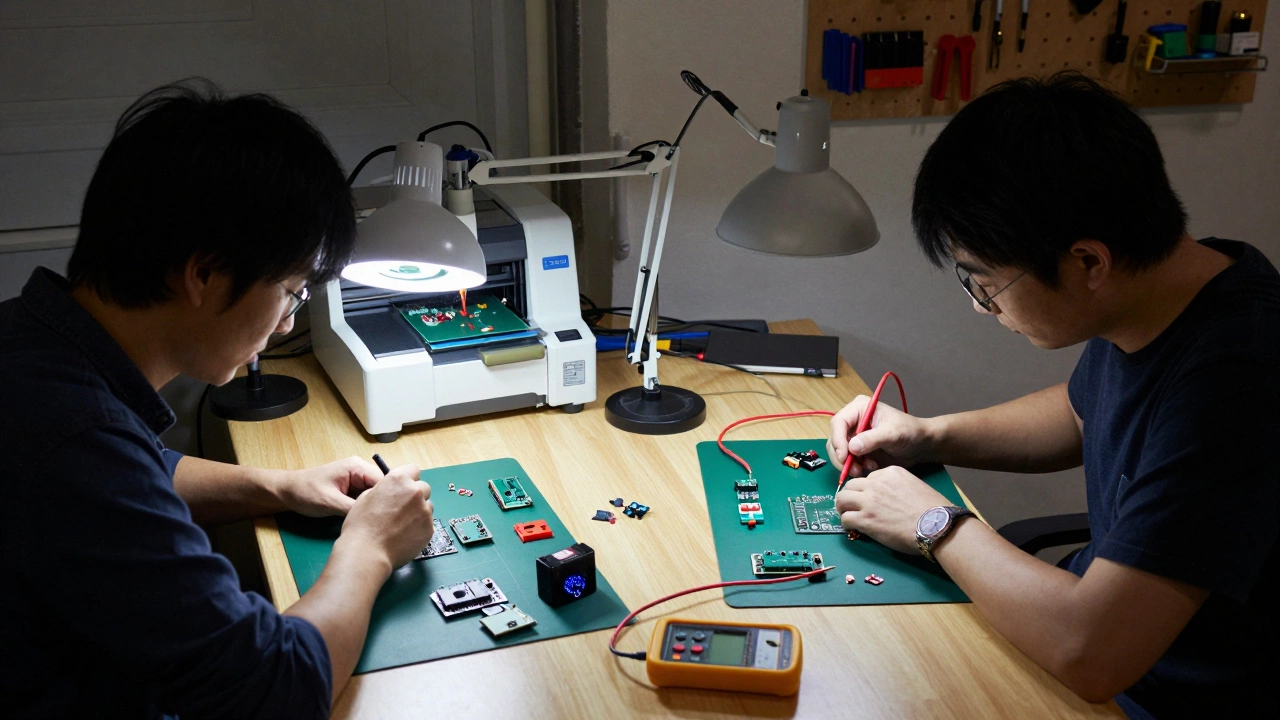

Custom Electronics Assembly: The Quiet Winner

Most people think electronics manufacturing is dominated by Foxconn and Samsung. But there’s a booming niche: custom circuit board assembly for specialized equipment. Think medical devices for vet clinics, irrigation controllers for small farms, or LED lighting systems for indoor growers.

A two-person shop in Wisconsin buys blank PCBs for $8 each, populates them with components (soldered by hand or a $1,500 pick-and-place machine), and sells them as complete units for $120. They make 200 units a month. Cost to produce? $35. Revenue? $24,000. Net profit? $18,000. And they’ve never spent a dollar on advertising. Their clients find them through trade shows and LinkedIn.

This works because big manufacturers won’t touch orders under 1,000 units. Small businesses need 50-200 units. That’s your market. You’re not competing with China - you’re serving the people who can’t get what they need from them.

Food Processing: More Than Just Jams and Pickles

Yes, hot sauce is profitable. But so are things like freeze-dried fruit snacks, plant-based protein powders, and gourmet spice blends. The key? Packaging and branding.

A woman in Oregon started making organic mushroom powder from locally foraged chanterelles. She dehydrates them in a food dehydrator, grinds them with a coffee grinder, and packages them in small glass jars with custom labels. Each 4-ounce jar costs $1.75 to make. She sells it for $28. Her monthly sales? 1,000 jars. Profit? $26,250.

She doesn’t sell in stores. She sells on Etsy, Instagram, and at farmers’ markets. Her customers aren’t looking for cheap - they’re looking for something unique, authentic, and healthy. That’s where the margin lives.

Plastic Injection Molding: Small Batches, Big Returns

Plastic manufacturing sounds expensive. But you don’t need a $500,000 injection molding machine. You can rent one by the hour at a local prototyping shop. Or buy a small tabletop machine for under $10,000.

One manufacturer in Indiana uses a $7,000 machine to make custom plastic clips for guitar straps. Each clip costs 18 cents to make. He sells them in packs of 10 for $15. That’s $1.50 per clip - an 733% markup. He sells 10,000 packs a year. Revenue: $150,000. Net profit: $110,000.

He doesn’t make toys or containers. He makes tiny parts that big companies outsource because they’re too niche. His customers? Music gear brands, pet product makers, and DIY hobbyists. He’s the hidden supplier behind dozens of popular brands.

Textile Printing: The New Craft Revolution

Textile manufacturing isn’t dead - it’s been reinvented. Digital textile printers now cost as little as $8,000. You can print custom designs on fabric, then cut and sew them into bags, aprons, or clothing.

A couple in Tennessee bought a used printer, started printing nature-themed designs on organic cotton tote bags, and sold them at craft fairs. Each bag costs $3.20 to make. They sell for $32. They produce 500 bags a month. Profit? $14,900. They now have a subscription box service where customers pick a new design every quarter. Their annual net profit? $180,000.

They don’t compete with H&M. They compete with boring, mass-produced bags. Their customers want art they can carry.

Why These Businesses Win

These aren’t lucky breaks. They follow a pattern:

- They solve a specific, underserved problem

- They sell directly to end users or niche B2B buyers

- They avoid competing on price - they compete on uniqueness

- They use automation only where it matters (labeling, packaging, simple assembly)

- They build customer loyalty through storytelling and transparency

The biggest mistake small manufacturers make? Trying to be everything to everyone. You don’t need to make 50 products. You need to make one thing exceptionally well - and find the people who’ll pay extra for it.

What Doesn’t Work Anymore

Some old ideas are dead or dying:

- Mass-producing plastic trinkets for Amazon FBA - saturated, low margin, high returns

- Printing t-shirts with generic quotes - oversaturated, low price point

- Assembling cheap electronics for big retailers - requires huge volume, thin margins

These used to work. Now, they’re profit killers. The market has shifted. Customers want authenticity, not bulk.

Getting Started - No Experience Needed

You don’t need an engineering degree or a business loan to start. Here’s how:

- Find a problem people are complaining about online (Reddit, Facebook groups, Amazon reviews)

- Make a simple version of a solution using existing tools (e.g., a spice blend, a custom clip, a topical cream)

- Test it with 10 people. If they’ll pay for it, scale slowly

- Use Etsy, Shopify, or local markets to sell - no need for a website at first

- Reinvest profits into better tools, not bigger space

One man in Alabama started making custom leather keychains from scrap material he found at a tannery. He spent $200 on tools. He sold 400 in six months. Now he employs three people and makes $180,000 a year. He never took a loan. He never ran an ad.

Final Thought: Profit Isn’t About Size - It’s About Focus

The most profitable manufacturing businesses in 2026 aren’t the biggest. They’re the most focused. They know exactly who they serve, what problem they solve, and why their customer pays more than the cheap alternative.

Don’t look for the biggest factory. Look for the smallest gap in the market - and fill it with something real, handmade, and meaningful. That’s where the money is.

What small-scale manufacturing has the highest profit margin?

Top profit margins come from specialty food products like artisanal hot sauce, CBD topicals, and organic spice blends - often exceeding 700-900% markup. Custom electronics assembly and niche plastic parts also offer 500-800% margins when sold directly to small businesses.

Can you make money with manufacturing on a small budget?

Yes. Many profitable small manufacturers start with under $5,000. A digital textile printer, a tabletop plastic molding machine, or a dehydrator for food products can be bought used or rented. The key is starting small, testing demand, and reinvesting profits - not spending on big equipment upfront.

Is food manufacturing profitable for small businesses?

Extremely. Small-batch food products like hot sauce, spice blends, and freeze-dried snacks have low ingredient costs and high perceived value. Many makers earn $150,000-$300,000 annually with just a home kitchen and online sales. Compliance is easier than you think - most states allow cottage food production for low-risk items.

What’s the easiest manufacturing business to start?

Custom spice blends or herbal salves. You need basic kitchen tools, a few ingredients, and a label printer. No special permits are needed in most places for non-medical, non-prescription products. You can test demand on Etsy or at local markets before scaling.

Why do most small manufacturers fail?

They try to compete on price instead of value. They chase volume instead of loyalty. And they spend money on inventory or equipment before proving people will buy. The winners focus on one product, one customer type, and one sales channel - then grow from there.

Start small. Solve one real problem. Build trust. Profit follows.