US vs China Manufacturing Comparison Calculator

United States

China

Manufacturing Comparison Results

The United States isn’t just a big economy-it’s the second-largest manufacturing power in the world. While China holds the top spot, the US still produces more manufactured goods than any other nation except one. In 2024, the US generated over $2.5 trillion in manufacturing output, accounting for roughly 15% of global production. That’s more than Japan, Germany, and South Korea combined. So when people ask, What is the US ranked in manufacturing?-the answer is clear: second.

How the US Stacks Up Against China

China has led global manufacturing since 2010, thanks to massive scale, low labor costs, and heavy government investment in infrastructure. In 2024, China’s manufacturing output hit $4.8 trillion. That’s nearly double the US number. But size isn’t everything. The US leads in high-value manufacturing: aerospace, semiconductors, pharmaceuticals, and advanced machinery. While China churns out cheap electronics and textiles, the US makes the engines for Boeing jets, the chips in Apple iPhones, and the biologics that treat cancer. The US doesn’t need to make everything-it makes what matters most.What Drives US Manufacturing Output

Three things keep US manufacturing strong: technology, skilled labor, and supply chain resilience. Factories in Ohio, Texas, and Michigan aren’t filled with hundreds of workers doing manual tasks. They’re packed with robots, AI-driven quality control systems, and automated assembly lines. A single Ford plant in Kentucky now produces more vehicles with 30% fewer workers than it did 15 years ago. Automation isn’t replacing jobs-it’s upgrading them. Today’s factory workers are technicians who program machines, not just push buttons.The US also benefits from a highly educated engineering workforce. Over 1 million engineers graduate from US universities every decade. That’s more than any other country. These engineers design the next generation of electric vehicles, medical devices, and renewable energy systems-all made in America.

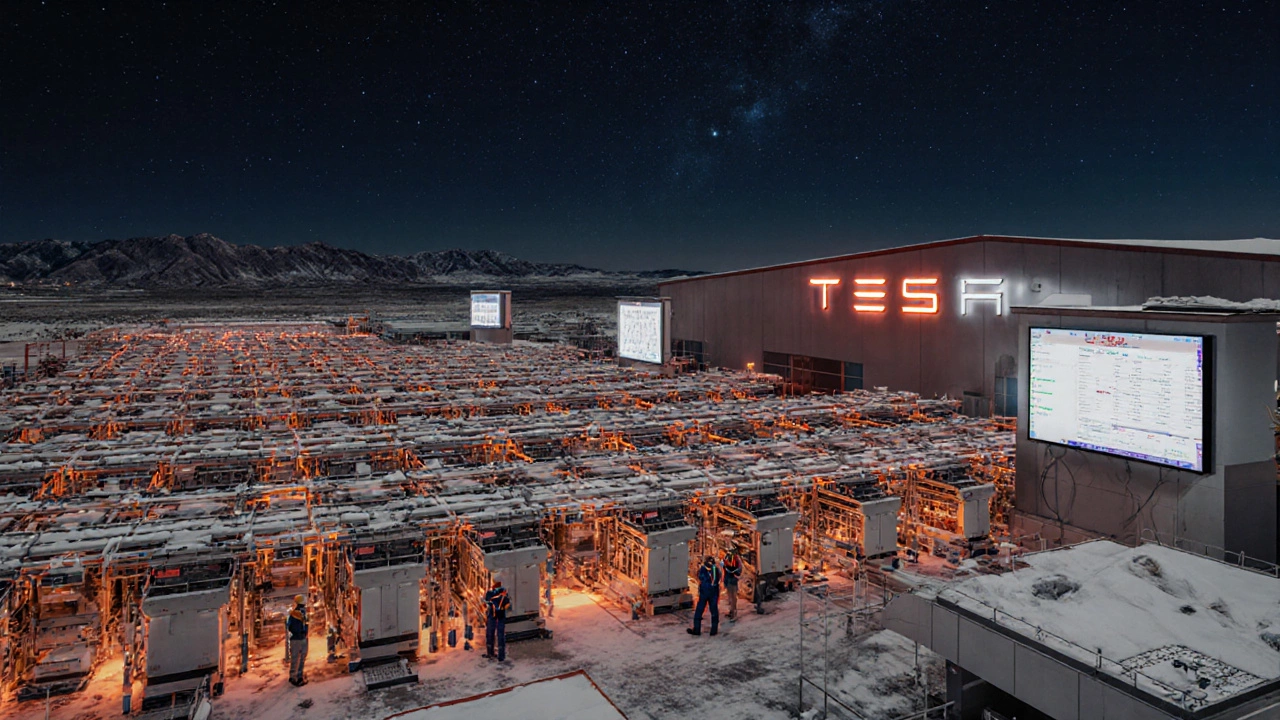

After the supply chain chaos of 2020-2022, companies started bringing production back home. The CHIPS Act, the Inflation Reduction Act, and state-level incentives have pushed over $500 billion in new manufacturing investments since 2021. TSMC built a $40 billion chip plant in Arizona. Intel is expanding its Ohio campus to $100 billion. Tesla’s Gigafactory in Nevada now produces more battery cells than any facility on Earth. These aren’t just factories-they’re national assets.

Top Industries Fueling US Manufacturing

Not all manufacturing is equal. Some sectors drive more value than others. Here are the top five industries powering US output:- Aerospace and Defense: Boeing, Lockheed Martin, and Northrop Grumman make planes, missiles, and satellites that no other country can match in volume or precision. This sector alone contributes over $300 billion annually.

- Pharmaceuticals: The US produces 40% of the world’s high-value drugs. Companies like Pfizer, Merck, and Johnson & Johnson operate massive, FDA-compliant facilities in New Jersey, North Carolina, and Pennsylvania.

- Electronics and Semiconductors: Even though most phones are assembled overseas, the chips inside them? A lot are designed and fabricated in the US. AMD, NVIDIA, and Intel control over 60% of the global market for high-end processors.

- Automotive: GM, Ford, and Tesla produce over 10 million vehicles a year. Electric vehicle production grew 35% in 2024 alone, with battery plants popping up across the Midwest and Southeast.

- Machinery and Industrial Equipment: Caterpillar, Cummins, and 3M make the heavy-duty tools, engines, and materials that keep global industry running. These aren’t flashy products, but they’re essential.

Why the US Doesn’t Need to Be #1

Some people think manufacturing rank is a race to the top. But the US doesn’t need to outproduce China in cheap plastic toys or basic textiles. It wins by making things that are hard to copy. A single jet engine made in Cincinnati costs $12 million. A smartphone chip made in Arizona sells for $500. These aren’t commodities-they’re intellectual property wrapped in metal and silicon.The US has shifted from being the world’s factory to being the world’s innovator. That’s a smarter long-term strategy. It’s why US manufacturing jobs pay 30% more on average than in China. It’s why US factories have lower turnover and higher productivity. You don’t compete on volume-you compete on value.

Challenges Still Facing US Manufacturing

Even with all its strengths, the US faces real hurdles. The biggest? Workforce gaps. There are over 800,000 open manufacturing jobs in the US right now. Many are skilled roles-welders, CNC operators, automation technicians-that don’t require a four-year degree but do require training. Community colleges and trade schools are stepping up, but not fast enough.Energy costs are another issue. Electricity in the US is cheaper than in Germany but more expensive than in China. Natural gas prices swing wildly, and that affects chemical and steel producers. The US needs more stable, affordable energy to stay competitive in energy-intensive industries.

Trade policy is tricky too. Tariffs on Chinese goods helped some US makers, but they also raised costs for American companies that rely on imported parts. A car maker in Michigan might pay 25% more for a Chinese-sourced sensor, even if it’s the only one that fits their design.

What’s Next for US Manufacturing?

The next five years will be decisive. The US is betting big on two trends: reshoring and automation. More than 1,200 companies have announced plans to bring production back from Asia since 2020. That’s not just about patriotism-it’s about speed, control, and risk reduction. If you make medical devices, you don’t want to wait six months for parts from halfway across the world during a pandemic.Automation will keep accelerating. By 2030, over 40% of US manufacturing tasks will be handled by robots or AI. That doesn’t mean fewer jobs-it means better jobs. Workers will train to manage robots, analyze data from sensors, and fix complex systems. The factory floor is becoming a tech hub.

Government policy will play a role too. The CHIPS Act is already paying off. The Inflation Reduction Act is pushing clean energy manufacturing. States like Georgia and Tennessee are offering tax breaks to attract battery and solar panel plants. The US isn’t just reacting-it’s building a new industrial base.

Final Thoughts

So, what is the US ranked in manufacturing? Second. But that’s misleading if you think it’s about quantity. The US is the world’s most advanced, most innovative, and most profitable manufacturing nation. It doesn’t need to make everything. It just needs to make the things no one else can make as well.The real question isn’t whether the US is #1. It’s whether it can keep leading in the areas that matter most. So far, the answer is yes.

Is the US still a major player in global manufacturing?

Yes. The US is the second-largest manufacturing nation in the world, behind only China. In 2024, it produced over $2.5 trillion in goods, making up about 15% of global output. It leads in high-value sectors like aerospace, pharmaceuticals, semiconductors, and advanced machinery.

Why does China rank higher than the US in manufacturing?

China ranks higher because it produces far more volume, especially in low-cost consumer goods like electronics, textiles, and household items. It benefits from massive government investment, a huge labor force, and decades of infrastructure development. But much of China’s output is lower-value compared to the US, which focuses on complex, high-margin products.

What industries make the US manufacturing sector strong?

The US leads in aerospace and defense, pharmaceuticals, semiconductors, automotive (especially electric vehicles), and industrial machinery. These industries rely on advanced technology, skilled labor, and intellectual property-areas where the US has a clear advantage over competitors.

Are US manufacturing jobs coming back?

Yes. Since 2020, over $500 billion in new manufacturing investments have been announced in the US, with major projects from TSMC, Intel, Tesla, and others. While automation reduces the need for low-skill labor, demand is rising for skilled technicians, engineers, and robotics operators. The number of open manufacturing jobs remains high-over 800,000 as of 2025.

How is automation changing US manufacturing?

Automation is making US factories faster, more precise, and more efficient. Robots handle repetitive tasks, while AI monitors quality in real time. This doesn’t eliminate jobs-it transforms them. Workers now train to operate and maintain advanced systems. The result? Higher productivity, better safety, and higher wages for those who adapt.

What role do government policies play in US manufacturing?

Government policies like the CHIPS Act and the Inflation Reduction Act are driving massive investment in domestic production. Tax credits, grants, and subsidies are helping companies build semiconductor plants, battery factories, and clean energy equipment in the US. These policies aim to reduce reliance on foreign supply chains and strengthen national security.