5S Implementation Calculator

Calculate Your 5S Benefits

Enter your facility details to estimate implementation time and potential benefits of the 5S system.

What You'll Discover

Based on your inputs, we'll estimate:

Ever walked into a food processing unit and felt like you stepped into a controlled environment where everything has its place? That’s not luck. It’s the 5S system at work. The 5S in food processing isn’t just a cleaning routine-it’s a proven method that keeps food safe, workers efficient, and inspections passing. If you’ve ever wondered why some factories never have rodent issues, why tools are always where you expect them, or why audits go smoothly, the answer starts with these five simple steps: Sort, Set in Order, Shine, Standardize, and Sustain.

Sort: Get Rid of What You Don’t Need

Sort is the first and most brutal step. It’s about asking: Do I really need this? In a food plant, clutter isn’t just messy-it’s dangerous. Old packaging materials, broken tools, expired cleaning supplies, and unused spare parts don’t just take up space. They become hiding spots for pests, collect dust that can contaminate products, and slow down emergency responses.

One meat processing plant in Staffordshire cut its pest-related shutdowns by 70% in six months just by removing every non-essential item from the production floor. They didn’t throw everything away-they tagged it. Anything not used in the last 30 days went to a designated holding area. If it wasn’t claimed in another 30 days, it was disposed of or recycled. No exceptions.

Think of it like your kitchen. If you keep ten spatulas you never use, you’ll waste time digging through them. In food processing, that wasted time can mean contaminated batches or missed deadlines.

Set in Order: Everything Has a Home

Once you’ve cleared the clutter, everything left gets a permanent, labeled home. This isn’t about neatness-it’s about speed and safety. In a high-speed packaging line, finding the right tool in 3 seconds instead of 30 seconds can mean the difference between hitting your daily quota and falling behind.

Shelves are marked with shadow boards so you can instantly see if a wrench is missing. Gloves are hung in color-coded zones by department. Bottles of sanitizer are placed exactly where they’re needed-right at the entrance to each production area, not tucked away in a storage closet. Labels use pictograms so workers who speak different languages can still find what they need.

A bakery in Birmingham switched to shadow boards for their mixing tools and reported a 40% drop in cross-contamination incidents. Why? Because when a tool isn’t in its spot, someone notices right away. No one has to ask, “Who took the dough scraper?” It’s obvious.

Shine: Clean as You Go, Not After the Fact

Shine doesn’t mean deep cleaning once a week. It means cleaning daily, during breaks, and after every shift. In food processing, dirt isn’t just ugly-it’s a legal risk. The UK Food Standards Agency doesn’t care if your floor looks nice. They care if there’s residue from last week’s batch of chicken broth stuck under the conveyor belt.

Every employee is responsible for cleaning their own area. Not just the janitorial staff. That means wiping down surfaces after each product change, sweeping up flour dust immediately, and checking drains for blockages. Cleaning schedules are posted visibly, and teams do a 10-minute “shine check” at the end of each shift.

One dairy plant in Derby reduced its microbial swab failures by 65% after implementing daily Shine routines. They didn’t buy new equipment. They just made sure every worker knew what “clean” looked like-and held each other accountable.

Standardize: Make It Repeatable

Once you’ve sorted, set in order, and started shining, you need to lock it in. That’s Standardize. This is where checklists, photos, and written procedures come in. You can’t rely on memory. You can’t rely on the “best” worker doing it right. You need everyone to do it the same way, every time.

Each station has a visual standard. A photo of a perfectly organized tool shelf. A checklist taped to the wall with boxes to tick off: “Sanitizer bottle full,” “Floor dry,” “Gloves in place.” These aren’t just paperwork-they’re training tools. New hires don’t learn from a 50-page manual. They learn by matching what they see on the wall to what they’re doing.

Standardization also means documenting the “why.” Why is the pressure washer stored under the sink? Because it’s too heavy to lift onto a high shelf. Why is the hand soap dispenser mounted at elbow height? Because it reduces strain and prevents spills. When people understand the reason, they follow the rule.

Sustain: Make It Stick

This is where most companies fail. They do 5S for a month, get a good audit score, then slowly slide back into old habits. Sustain is the hardest part. It’s not about one-time training. It’s about culture.

The best food processors make 5S part of daily life. Managers do daily 5S walk-throughs-not as inspections, but as conversations. “What’s been working? What’s still tricky?” Teams rotate who leads the weekly 5S review. Small wins are celebrated. A team that went 30 days without a tool misplacement gets a coffee voucher. A department that reduced cleaning time by 20% gets their name on a “5S Champion” board.

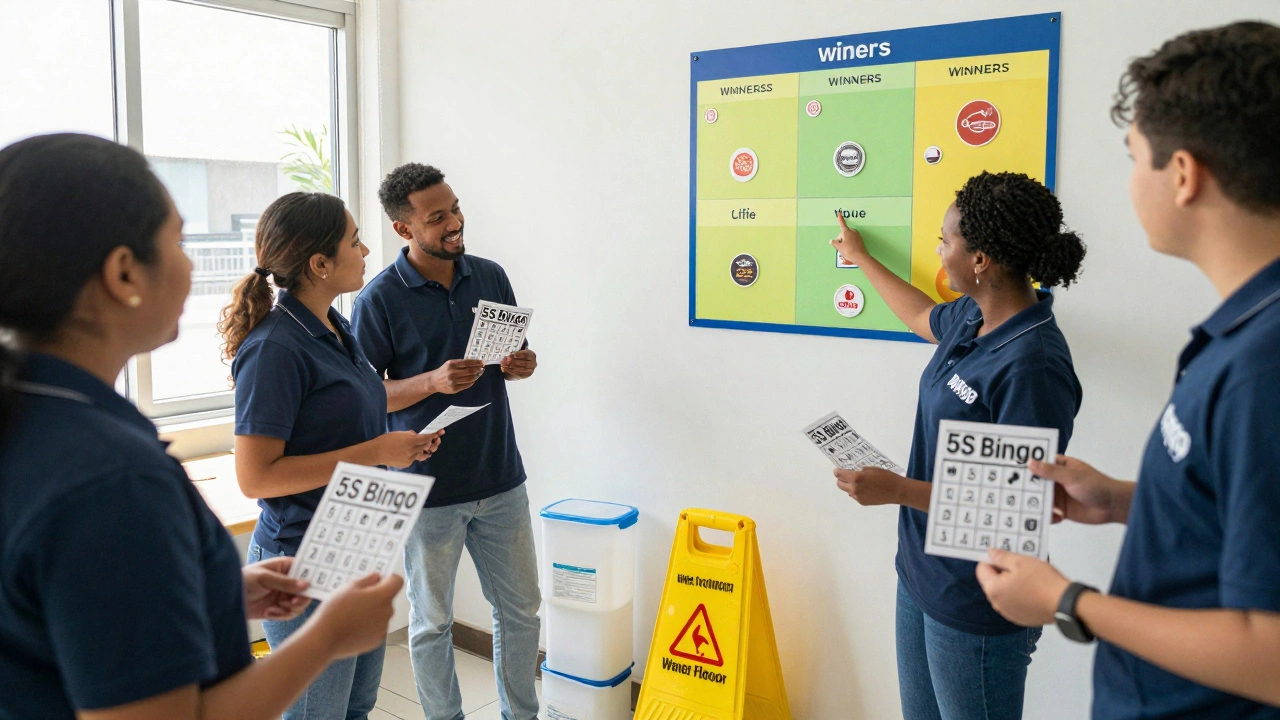

At a fish processing plant in Grimsby, they started a “5S Bingo” game. Workers got a card with 10 common 5S violations-like “unlabeled container,” “wet floor,” “tool out of place.” Every time someone spotted one, they marked it. At the end of the week, the person with the most marks won a prize. It turned compliance into a team sport.

Why 5S Matters More in Food Processing Than Anywhere Else

Other industries use 5S. But in food, the stakes are higher. A mislabeled container of bleach in a car factory? Annoying. In a food plant? A single mistake can trigger a recall, hurt customers, and shut down your business.

The UK’s Food Safety Act 2013 and EU Regulation (EC) No 852/2004 require businesses to have systems in place to prevent contamination. 5S isn’t optional-it’s the foundation. It’s the reason auditors give you a clean bill of health. It’s why you don’t get fined. It’s why your customers trust your brand.

And it’s not expensive. You don’t need new machines. You don’t need consultants. You need commitment. You need to treat your workspace like a kitchen where every surface is touched by food. Because it is.

Common Mistakes to Avoid

Even smart teams mess up 5S. Here’s what not to do:

- Doing it once and calling it done. 5S isn’t a project. It’s a habit.

- Letting managers off the hook. If the boss doesn’t follow the rules, no one else will.

- Using vague labels. “Tools” isn’t good enough. “Meat Cutter Blade Set - Station 3” is.

- Ignoring the human factor. If workers feel like 5S is just more work, it won’t last. Make it easier, not harder.

Getting Started with 5S in Your Facility

Here’s how to begin:

- Choose one small area to start-maybe a tool storage shelf or a single packaging line.

- Get the team involved. Let them decide what stays and what goes.

- Take before and after photos. People remember visuals.

- Set a 30-day goal. At the end, celebrate the win.

- Then move to the next area.

You don’t need to fix everything at once. You just need to start. And once you see how much smoother things run, you’ll wonder how you ever worked any other way.

Is 5S only for large food processing plants?

No. 5S works for any size operation-from a small bakery making 50 loaves a day to a factory producing millions. In fact, smaller facilities often see faster results because there’s less inertia to overcome. The principles are the same: remove clutter, organize what’s left, clean daily, write it down, and keep it up.

Do I need special software or tools to implement 5S?

No. 5S is low-tech by design. You need sticky notes, labels, tape, paint, and photos. Some places use free apps to track progress, but the core of 5S is visual and physical. The goal is to make problems obvious, not to create digital reports.

How long does it take to see results from 5S?

You’ll notice changes in days. Tools are easier to find. Floors look cleaner. After 30 days, most teams report less stress, fewer mistakes, and faster cleanups. Major improvements-like fewer safety incidents or audit passes-usually show up in 3 to 6 months.

Can 5S help with food recalls?

Yes. When you know exactly where every ingredient, tool, and batch is stored, tracing contamination becomes faster and more accurate. A well-organized facility can isolate a problem in hours instead of days. That means fewer products recalled, less money lost, and better customer trust.

Is 5S the same as ISO 22000 or HACCP?

Not exactly. ISO 22000 and HACCP are formal food safety management systems focused on hazard control. 5S is about workplace organization. But they work together. 5S creates the clean, orderly environment that makes HACCP controls easier to follow. You can’t have a good HACCP plan if your tools are buried under boxes.

Next Steps: Start Small, Think Big

Don’t wait for a big audit or a near-miss to act. Pick one corner of your facility. Clear it out. Label it. Clean it. Take a photo. Show your team. Ask them what they think. That’s how real change starts.

The best food processors don’t win because they have the fanciest machines. They win because they’ve turned chaos into calm. And it all begins with five simple words: Sort, Set, Shine, Standardize, Sustain.