BOM vs MOM Comparison Tool

Compare BOM vs MOM Features

Explore the key differences between Bill of Materials and Manufacturing Operations Management across multiple aspects.

Bill of Materials (BOM)

What components are needed for the product

Example: Lists every component, sub-assembly, raw material, and quantity needed to build a finished product

Why it matters: Acts as the recipe card for production, providing precise details for manufacturing

Manufacturing Operations Management (MOM)

How production is executed and optimized

Example: Coordinates, monitors, and optimizes the entire production floor

Why it matters: Tells you how, when, and where to build it for maximum efficiency

Ever wonder why some factories obsess over a BOM vs MOM comparison while others seem to skip it altogether? The short answer is that each serves a distinct purpose in the production chain. Getting clear on what separates a Bill of Materials (BOM) from Manufacturing Operations Management (MOM) can save you time, money, and a lot of headaches when you’re navigating UK government schemes or planning a new line.

What is a Bill of Materials (BOM)?

Bill of Materials (BOM) is a structured list of every component, sub‑assembly, raw material, and quantity needed to build a finished product. Think of it as the recipe card for a mechanical sandwich - it tells you exactly what goes in, how much, and in what order. Key attributes include:

- Hierarchy: Parent‑child relationships that map sub‑assemblies to the final product.

- Quantities: Precise count of each item required per unit.

- Part numbers: Unique identifiers that link to inventory systems.

- Version control: Tracks changes when product designs evolve.

In the UK, many government schemes such as the Made Smarter programme ask manufacturers to submit a BOM when applying for digital transformation grants. It proves you have a clear, auditable design ready for automation.

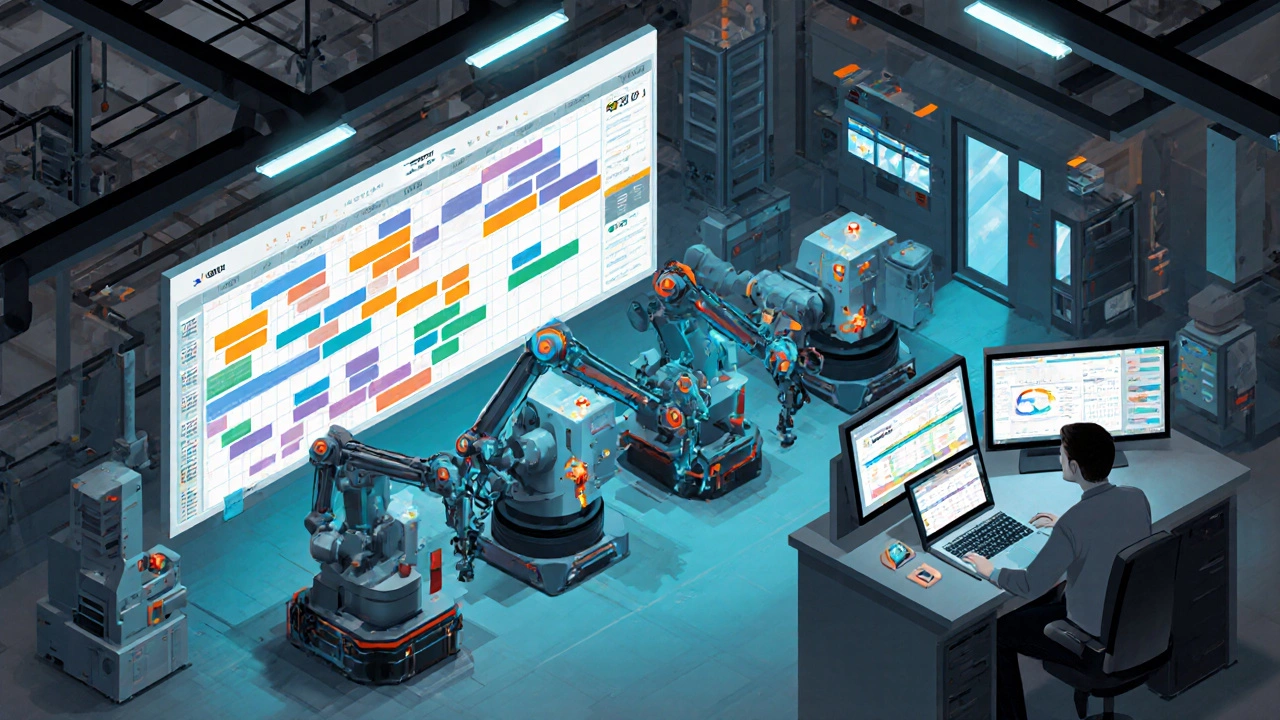

What is Manufacturing Operations Management (MOM)?

Manufacturing Operations Management (MOM) is a suite of processes and software that coordinates, monitors, and optimizes the entire production floor. While a BOM tells you *what* to build, MOM tells you *how*, *when*, and *where* to build it. Core functions include:

- Scheduling: Real‑time allocation of machines, labor, and materials.

- Execution: Directs shop‑floor equipment through Manufacturing Execution Systems (MES).

- Quality & compliance: Captures data for traceability and regulatory reporting.

- Performance analytics: Dashboards that drive continuous improvement.

MOM platforms often integrate with ERP, PLM, and SCM tools to create a seamless digital thread. The UK government’s Innovate UK funding for smart factories frequently requires a MOM roadmap as part of the application.

Side‑by‑Side Comparison

| Aspect | Bill of Materials (BOM) | Manufacturing Operations Management (MOM) |

|---|---|---|

| Primary focus | What components are needed | How production is executed and optimized |

| Typical users | Design engineers, procurement | Shop‑floor supervisors, production planners |

| Key data | Part numbers, quantities, hierarchy | Schedule, equipment status, quality metrics |

| Integration points | ERP, PLM | ERP, MES, SCADA, IoT sensors |

| Government scheme relevance | Proof of design for grant eligibility | Digital transformation roadmap for funding |

Notice how the two aren’t competing tools - they’re complementary. A robust BOM feeds accurate data into MOM, and MOM’s visibility helps keep the BOM up‑to‑date during production changes.

How BOM and MOM Fit Into the Wider Technology Landscape

To truly leverage both, manufacturers often stitch together a tech stack that includes several related systems. Below are the most common companions:

- Enterprise Resource Planning (ERP) manages finance, HR, and supply chain data.

- Manufacturing Execution System (MES) is the real‑time execution engine that MOM relies on.

- Product Lifecycle Management (PLM) stores design files, version history, and change requests.

- Supply Chain Management (SCM) coordinates inbound logistics and demand forecasting.

- Industry 4.0 concepts bring IoT, AI, and digital twins into the mix.

- Lean Manufacturing principles guide waste reduction and continuous improvement.

When you map these together, the BOM lives at the base of the design hierarchy, PLM and ERP keep it accurate, and MOM drives the shop‑floor based on live data from MES and IoT sensors.

Practical Steps to Align BOM and MOM in Your Business

- Audit your current BOM data. Ensure each part number matches what’s in your ERP and PLM systems.

- Choose a MOM platform that integrates with existing tools. Look for pre‑built connectors to ERP, MES, and IoT gateways.

- Map process flows. Document how a BOM change triggers updates in MOM schedules.

- Run a pilot line. Use a single product family to validate the data flow from design to execution.

- Apply for relevant UK funding. The Made Smarter and Innovate UK programmes reward projects that demonstrate end‑to‑end digital integration.

Following these steps helps you avoid the classic pitfall of “orphaned” BOMs that sit in a spreadsheet while the shop floor runs on outdated information.

Common Pitfalls and How to Avoid Them

- Static BOMs. Treat the BOM as a living document. Automate updates via PLM change orders.

- Missing real‑time data. Connect MOM to IoT sensors for machine status; otherwise you’ll be scheduling on guesses.

- Over‑complicating the stack. Start with core integrations (ERP ↔ MOM ↔ MES) before adding AI or advanced analytics.

- Ignoring regulatory traceability. Both BOM and MOM must capture batch numbers for compliance with UK MHRA or CE marking.

Future Trends: Where BOM and MOM Are Heading

By 2027 most UK manufacturers will have a “digital twin” of their product line. In that world, the BOM becomes a dynamic data model feeding AI‑driven MOM engines that auto‑optimise schedules based on demand spikes, energy costs, or equipment health. Staying ahead now means investing in platforms that support this level of interoperability.

Is a BOM required for all types of manufacturing?

Yes. Whether you’re assembling electronics, casting metal parts, or baking food, a BOM provides the essential list of materials and quantities needed for each product unit.

Can MOM replace an ERP system?

No. MOM focuses on shop‑floor execution, while ERP handles finance, HR, and broader supply‑chain functions. The two are meant to work together.

Which UK government scheme is best for funding MOM implementation?

Innovate UK’s Smart Manufacturing programme specifically supports MOM and MES deployments that demonstrate productivity gains and digital integration.

How often should a BOM be reviewed?

Ideally whenever a design change occurs. Many firms schedule quarterly audits to align with version control in PLM.

What data does MOM collect for quality control?

MOM logs machine parameters, operator actions, timestamps, and inspection results, creating a traceable record for each produced unit.