Manufacturing in 2025: Key Trends, Schemes, and Materials Driving India's Industry

When you think about manufacturing, the process of turning raw materials into finished goods at scale. Also known as industrial production, it's the backbone of India's economy and a major force in global supply chains. In 2025, it’s not just about making more—it’s about making smarter. From government incentives that help small factories survive to corporations still pushing single-use plastic despite the damage, the industry is at a crossroads. And in India, the choices manufacturers make right now will shape everything from local jobs to environmental impact for decades.

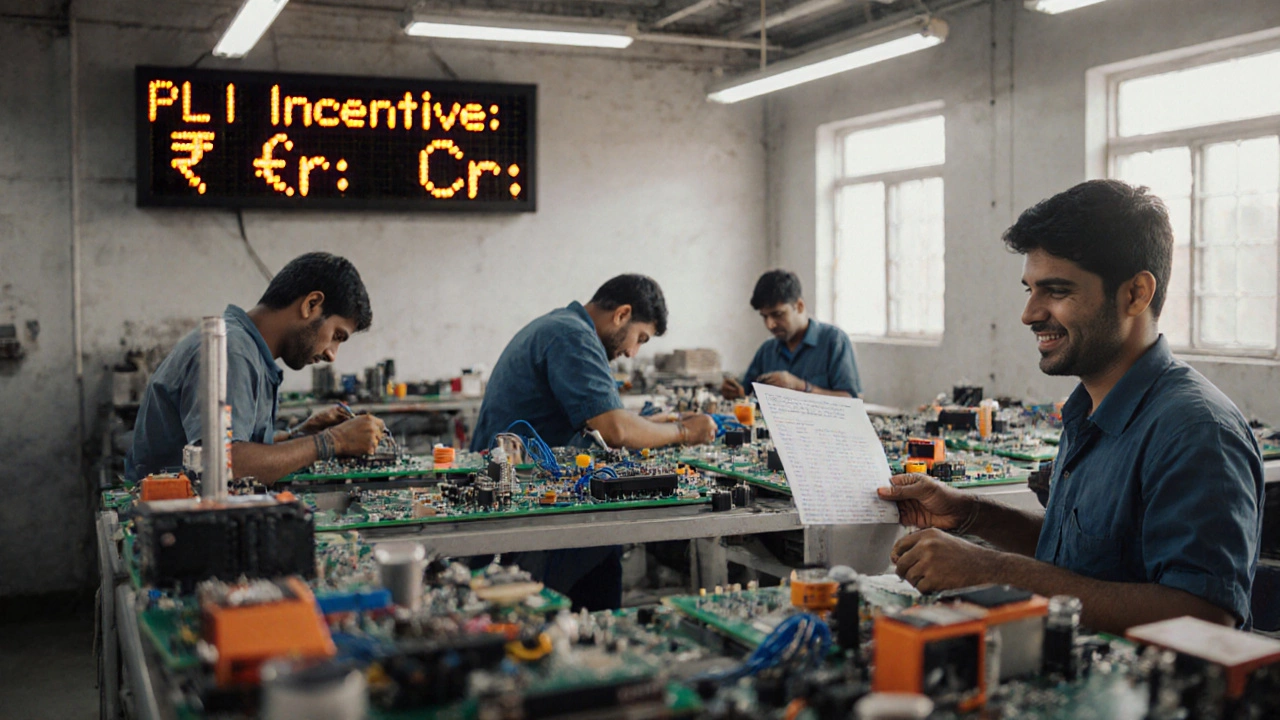

Government manufacturing schemes, targeted programs designed to boost small and medium factories through funding, tax breaks, and training. Also known as MSME support programs, it's the lifeline for thousands of small workshops across Tamil Nadu, Gujarat, and Uttar Pradesh. The PLI scheme, PMEGP, and PPE aren’t just acronyms—they’re real tools that let a small metal workshop in Ludhiana afford a new CNC machine or a textile unit in Tirupur upgrade to energy-efficient looms. Meanwhile, plastic pollution, the environmental crisis caused by corporate overproduction of disposable plastic. Also known as single-use plastic waste, it’s not caused by you throwing away a bottle—it’s caused by companies making 400 million tons of it every year, most of it never recycled. That’s why posts this month dug into who’s really behind the mess, and why recycling alone won’t fix it.

On the ground, manufacturers are making tough calls. In furniture shops across North India, cheapest wood for furniture, affordable timber options like poplar, rubberwood, and BWP plywood used by budget-conscious makers. Also known as low-cost timber for manufacturing, it’s the difference between staying open and shutting down. And while U.S. states like Texas and Tennessee race ahead with automation and state incentives, India’s chemical hubs in Jamnagar and Dahej are quietly powering global plastics, dyes, and pharma intermediates. The textile industry? It’s booming—not because of tradition, but because of exports, automation, and PLI-backed tech upgrades. Meanwhile, the most profitable small-scale product isn’t jewelry or candles—it’s custom-engraved pet tags and water bottles, with margins over 1,000% and almost no overhead.

What ties all this together? It’s not luck. It’s strategy. Whether you’re sourcing wood for a new line of shelves, applying for a government grant, or fighting back against plastic waste, the moves you make in 2025 are built on the same foundation: knowing what works, who’s behind it, and where the real opportunities lie. Below, you’ll find the real stories, the hard numbers, and the no-BS insights from manufacturers who are doing it right—right now.

Discover the cheapest woods for furniture manufacturing in India in 2025, including poplar, rubberwood, and BWP plywood. Learn where to buy, what to avoid, and how to maximize profit on a budget.

Discover the top U.S. states with the fastest manufacturing growth in 2025, including Tennessee, Texas, and North Carolina, and learn why location, workforce training, and state incentives are key to success.

The 4 P's of manufacturing government schemes-PLI, PMEGP, PMMY, and PPE-are key support programs for Indian MSMEs. Learn how each works, who qualifies, and how to claim benefits in 2025.

India's textile industry is booming in 2024, driven by exports, automation, and government support. Learn how technical textiles, PLI schemes, and sustainability are reshaping the sector.

The most lucrative thing to sell in small-scale manufacturing isn't what you think-custom engraved metal goods like pet tags and water bottles offer 1,000%+ margins, low overhead, and repeat customers. Here's how to start profitably.

Plastic pollution isn't caused by consumers - it's designed by corporations. Learn who really produces the plastic waste choking our planet and why recycling alone won't fix it.

The US is the second-largest manufacturing nation in the world, producing over $2.5 trillion in goods annually. It leads in high-value industries like aerospace, semiconductors, and pharmaceuticals, not volume.

Jamnagar and Dahej in Gujarat are India’s top chemical manufacturing hubs, producing over 80% of the country’s petrochemicals and handling most chemical exports. Home to giants like Reliance, the region makes plastics, dyes, fertilizers, and pharmaceutical intermediates used worldwide.

Learn the three main types of manufacturers - discrete, process, and job shop - and how each one operates, scales, and serves different markets. Essential reading for business owners and industry professionals.