MOM in Manufacturing: What It Means and Why It Matters

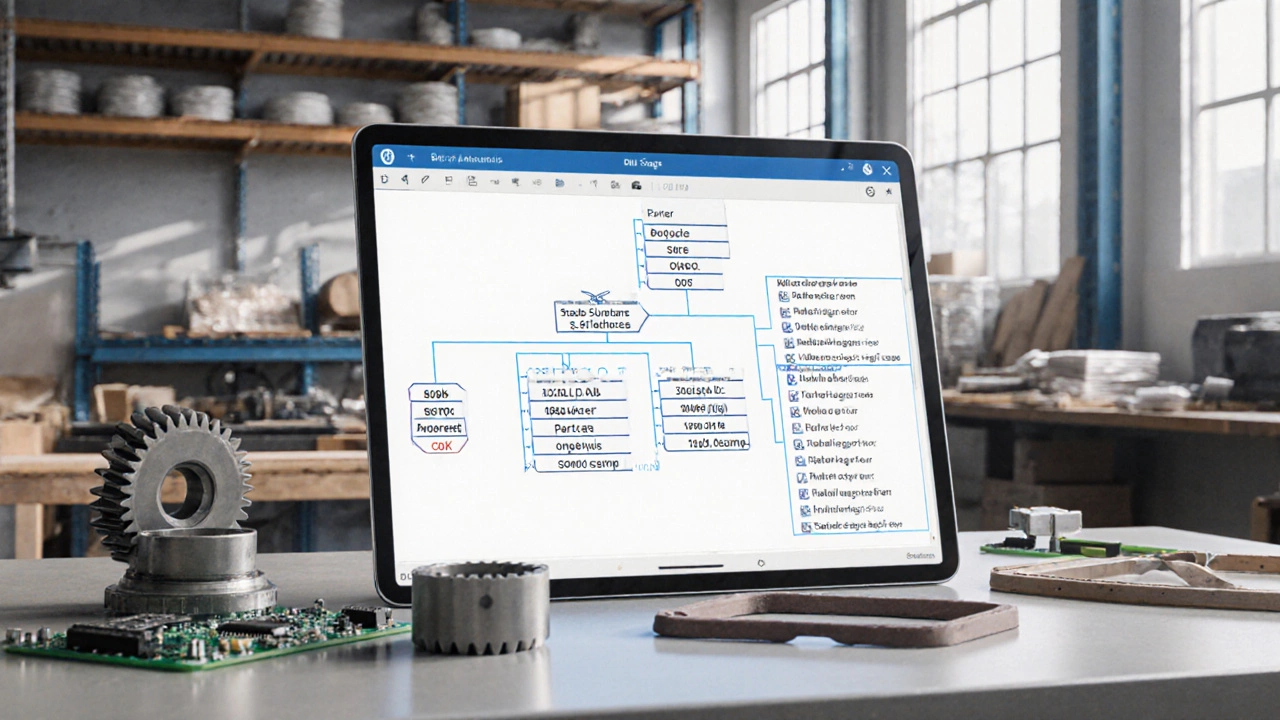

When you hear MOM, Manufacturing Operations Management. It's not just a buzzword—it's the backbone of every modern factory that runs on time, on budget, and without chaos. Think of it as the central nervous system for production. It connects the shop floor to the boardroom, turning raw materials into finished goods with fewer mistakes, less downtime, and more speed.

MOM isn’t software you install once and forget. It’s a living system that tracks everything: who ran which machine, when the raw material arrived, how many units passed inspection, and why a line shut down at 3 a.m. It’s what lets a plant in Gujarat produce 10,000 plastic components a day without missing a beat. And it’s why companies like Tirupati Polymers can deliver consistent quality to clients across India. Without MOM, you’re flying blind—guessing when to reorder, hoping machines don’t break, and praying your team doesn’t make a costly error.

Related systems like manufacturing software, digital tools that monitor and control production workflows and industrial automation, using machines and sensors to reduce human intervention in repetitive tasks are part of MOM’s ecosystem. They don’t replace people—they give them better data. A worker can now see in real time if a mold is overheating instead of waiting for a product to fail. A manager can spot a drop in output across three plants before the weekly report even comes out. And that’s the power of MOM: turning noise into action.

You’ll find this theme across the posts below. From how Gujarat’s chemical hubs use real-time tracking to boost output, to why small manufacturers in Tamil Nadu are skipping old-school paper logs for digital systems, MOM is quietly reshaping India’s industrial landscape. It’s not about fancy robots or AI hype—it’s about making sure the right thing happens at the right time, every time. Whether you’re running a single machine or managing a multi-site plant, understanding MOM isn’t optional anymore. It’s the difference between staying ahead and falling behind.

Learn the key differences between a Bill of Materials (BOM) and Manufacturing Operations Management (MOM), how they work together, and which UK schemes support them.

Find out what sets MES (Manufacturing Execution Systems) apart from MOM (Manufacturing Operations Management), with real-world insights and tips for your factory.