Difference in Manufacturing: What Sets Industries Apart

When people talk about manufacturing, the process of turning raw materials into finished goods. Also known as industrial production, it’s not one single thing — it’s many different systems working in very different ways. Some factories make millions of identical plastic parts. Others hand-assemble custom metal tags in a garage. One produces chemicals for global pharmaceuticals. Another makes textiles for local markets. The difference isn’t just in size — it’s in purpose, method, and impact.

Take polymer production, the chemical process of creating synthetic materials like plastics and resins. Also known as plastic manufacturing, it’s a high-volume, high-temperature operation that needs precise control and large infrastructure. This isn’t the same as small-scale manufacturing, small operations that make niche products with low overhead and high margins. Also known as micro-manufacturing, it’s about agility, not volume — think engraved pet tags or custom water bottles made in batches of 50, not 50,000. Then there’s the chemical industry, the backbone of paints, fertilizers, dyes, and pharmaceutical intermediates. Also known as process manufacturing, it’s where Gujarat dominates India’s output, with plants running 24/7 to feed global supply chains. These aren’t just different businesses — they’re different worlds with different rules, costs, and risks.

One thing they all share? They’re shaped by policy, geography, and demand. The US leads in high-value manufacturing like semiconductors, while India’s strength lies in textiles and polymer goods made for local and export markets. Government schemes like PLI and PMEGP don’t help every type of manufacturer the same way. A giant polymer plant in Dahej needs different support than a tiny workshop in Jaipur making custom metal goods. The difference in scale doesn’t just affect output — it affects who gets help, who gets taxed, and who can actually survive.

What you’ll find below are real examples of how these differences play out — from why Gujarat leads chemical production to how a single entrepreneur made $10,000 selling engraved pet tags. You’ll see how plastic pollution isn’t about consumers, but about who designs the packaging. You’ll learn why the top steel company isn’t the biggest by volume, and why the fastest-growing manufacturing states aren’t the ones you expect. This isn’t theory. It’s what’s happening right now, in factories across India and beyond — and understanding the difference is the first step to making smarter choices, whether you’re buying, selling, or building something yourself.

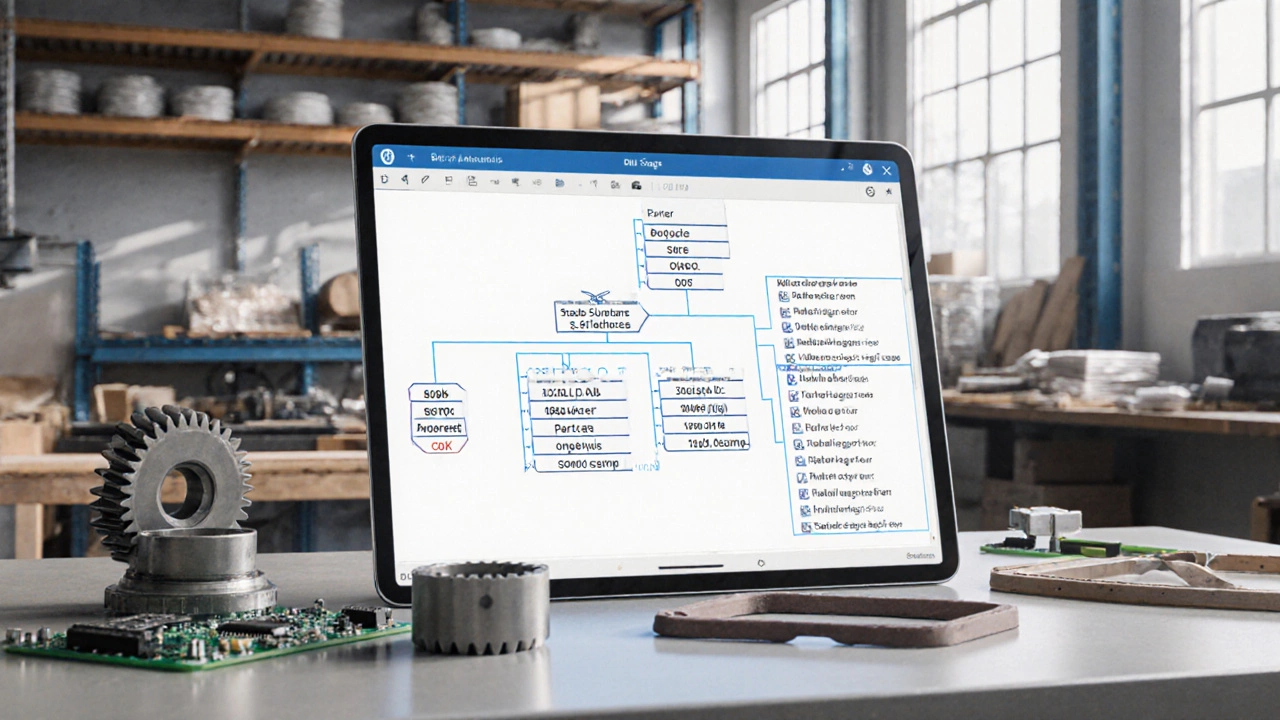

Learn the key differences between a Bill of Materials (BOM) and Manufacturing Operations Management (MOM), how they work together, and which UK schemes support them.