BOM in Manufacturing: What It Is, Why It Matters, and How It Powers Production

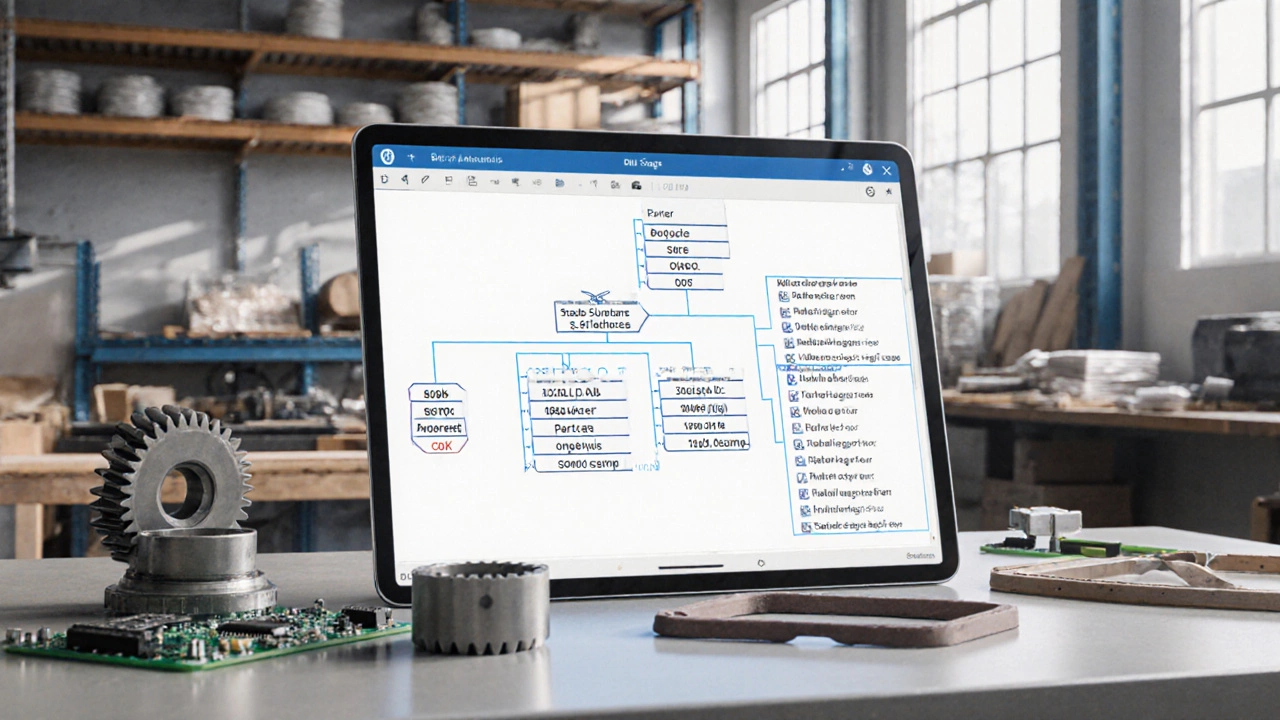

When you think about making something—whether it’s a plastic container, a textile roll, or a car part—you’re not just assembling parts. You’re following a bill of materials, a detailed list of raw materials, components, and instructions needed to build a product. Also known as BOM, it’s the blueprint that turns an idea into a physical thing. Without it, factories would be guessing what to buy, when to order, and how much to use. And that’s a recipe for waste, delays, and lost money.

The BOM doesn’t just list parts. It ties directly to how companies like Tirupati Polymers manage their polymer production. It tells them exactly how much resin, additives, or colorants go into each batch. It links to production planning, the process of scheduling and allocating resources to meet manufacturing goals. If the BOM is wrong, the entire schedule breaks. That’s why top manufacturers don’t treat it as an afterthought—they treat it as the core of their operation. It’s also connected to manufacturing process, the step-by-step methods used to transform materials into finished goods. A single BOM can have dozens of versions, each matching a different product line, machine setup, or customer requirement.

Look at the posts here. You’ll see discussions about small-scale manufacturing, chemical production in Gujarat, and textile exports—all of them depend on accurate BOMs. A startup making engraved pet tags needs to know exactly how much metal and ink to order. A polymer plant in Dahej must track resin grades, stabilizers, and packaging materials down to the kilogram. Even companies exporting textiles rely on BOMs to match fabric weights, thread counts, and dye batches to international orders. It’s not glamorous, but it’s the invisible engine behind every successful product.

What you’ll find in this collection isn’t theory. It’s real-world insight from manufacturers who’ve learned the hard way that a typo in a BOM can cost thousands. You’ll learn how to build one that actually works, how to avoid common mistakes, and how top Indian factories use it to stay ahead. Whether you’re running a small workshop or managing a large production line, understanding the BOM isn’t optional—it’s your first step to getting it right.

Learn the key differences between a Bill of Materials (BOM) and Manufacturing Operations Management (MOM), how they work together, and which UK schemes support them.