Manufacturing Support: Tools, Systems, and Strategies That Keep Factories Running

When you think of manufacturing, you picture machines, assembly lines, and workers—but manufacturing support, the hidden backbone that keeps production running without breakdowns, delays, or waste. Also known as production support, it’s what happens behind the scenes to make sure the line never stops. It’s not glamorous, but without it, even the most advanced factory grinds to a halt. Think of it like the crew that refuels a jet mid-flight—you don’t see them, but the plane wouldn’t fly without them.

Manufacturing support isn’t one thing. It’s a mix of Manufacturing Operations Management (MOM), the digital systems that track every step from raw material to finished product, and Bill of Materials (BOM), the detailed recipe that tells you exactly what parts, tools, and time each product needs. These aren’t just software buzzwords—they’re the reason companies like Reliance in Gujarat or Arvind Ltd. in Maharashtra can hit targets day after day. When a textile mill in Surat needs to switch from cotton to polyester, MOM updates the schedule, BOM changes the parts list, and maintenance teams prep the machines—all before the shift starts.

It’s also about people. Skilled technicians who fix broken injection molders in seconds. Planners who balance raw material orders so nothing sits idle. Quality teams that catch a 0.1% defect before it hits the shipping dock. In India, where small-scale manufacturers are booming, manufacturing support means knowing how to stretch limited budgets—using low-cost automation, training workers on multi-role tasks, and keeping machines alive longer than their warranty. That’s why posts on this page cover everything from the 5 Ps of manufacturing (Product, Process, Plant, People, Planning) to how Gujarat’s chemical hubs rely on flawless logistics and maintenance routines.

And it’s not just about fixing problems—it’s about preventing them. The best manufacturing support systems predict failures before they happen. They use data from sensors, historical downtime logs, and real-time output rates to adjust workflows. That’s why you’ll find posts here about why the US leads in high-value manufacturing—not because it has more factories, but because it invests in smarter support systems. It’s also why plastic pollution isn’t just a consumer issue—it’s a design flaw in how products are made, tracked, and recycled. Good manufacturing support asks: Can this part be reused? Can this process use less energy? Can we make it cheaper without cutting corners?

On this page, you’ll find real-world examples of how manufacturers in India and beyond are solving these problems. From startups inventing high-margin products with minimal overhead to giants like ArcelorMittal optimizing steel production, the thread tying it all together is manufacturing support. It’s the quiet force behind every on-time delivery, every cost cut, every innovation that actually ships. No fluff. No theory. Just what works—today, in real factories, with real people.

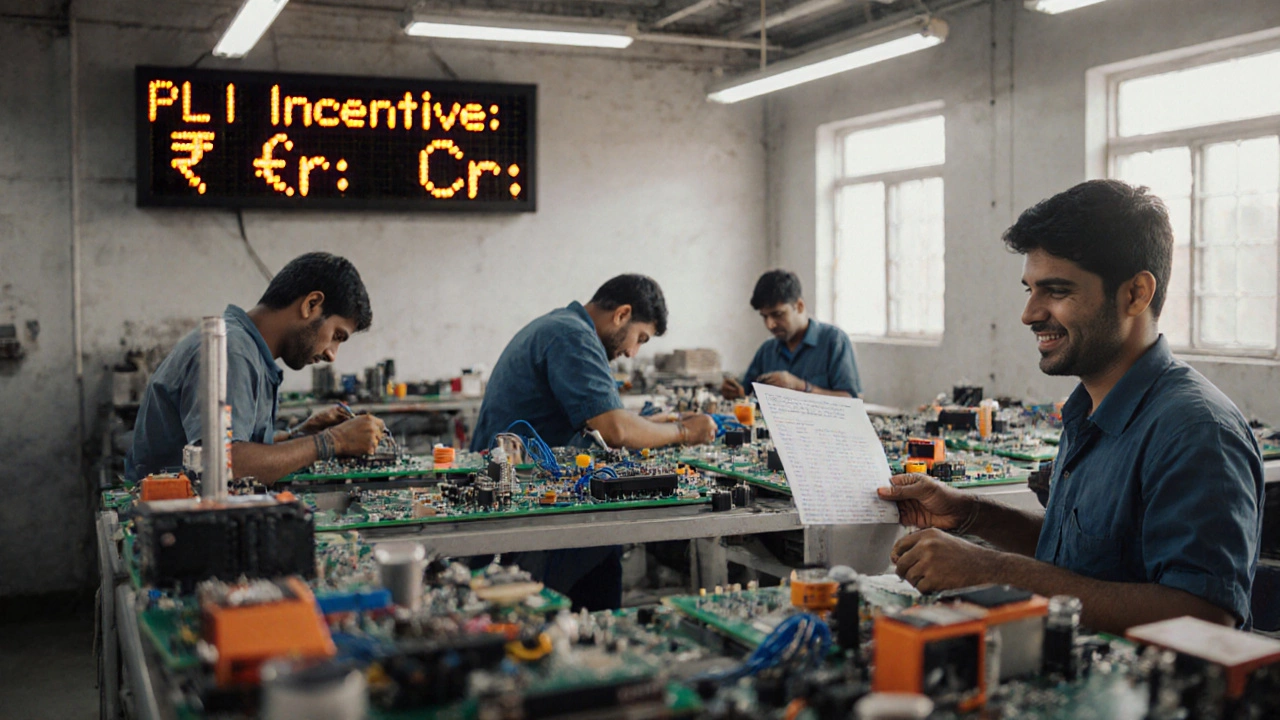

The 4 P's of manufacturing government schemes-PLI, PMEGP, PMMY, and PPE-are key support programs for Indian MSMEs. Learn how each works, who qualifies, and how to claim benefits in 2025.